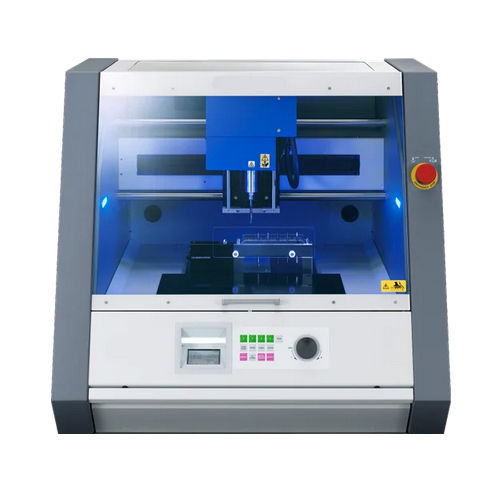

Desktop Milling Machine

Price 280000 INR/ Piece

Desktop Milling Machine Specification

- Product Type

- Desktop Milling Machine

- General Use

- Industrial & Commercial

- Weight (kg)

- 19.6 Kilograms (kg)

- Automatic

- Yes

- Control System

- PLC Control

- Table Size

- 9.14x6.17 Inch

- Feature

- High Performance, High Efficiency

- Color

- White

- Warranty

- 1 Years

Desktop Milling Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- 3000 Pieces Per Month

- Delivery Time

- 1 Week

- Main Domestic Market

- All India

About Desktop Milling Machine

A Desktop Milling Machine is a compact and versatile machine tool used for cutting, shaping, and drilling various materials with precision. It is typically smaller in size compared to larger industrial milling machines, making it suitable for small-scale machining tasks and hobbyist use. These machines come with safety features such as emergency stop buttons, protective covers, and interlocks to prevent accidental starts or access to moving parts. The worktable is where the workpiece is secured during machining and allows for more efficient cutting and machining. Desktop Milling Machine come in a range of prices depending on their features, specifications and build quality.

| Product Type | Milling Machine |

| Usage/Application | Modeling Wax, Chemical Wood, Foam, Acrylic, Poly acetate, ABS, PC board |

| Automation Grade | Automatic |

| Voltage | DC24V, 2.5A |

| Table Size | 9.14 (X) x 6.17 (Y) inches |

| Weight | 19.6 kg |

Advanced PLC Control for Seamless Operation

The machine incorporates a sophisticated PLC control system, automating complex milling tasks for enhanced productivity. This technology minimizes human error and ensures each project is completed with pinpoint accuracy.

Optimized for High Efficiency and Performance

Engineered for maximum efficiency, this milling machine minimizes energy consumption while maintaining robust throughput, making it an economical choice for busy workshops and manufacturing units.

Compact yet Powerful

Weighing just 19.6 kg and featuring a modest table size, this desktop milling machine balances space-saving design with substantial machining power, making it suitable for diverse industrial and commercial environments in India.

FAQ's of Desktop Milling Machine:

Q: How does the automatic PLC control system improve the milling process?

A: The automatic PLC control system streamlines operations by precisely managing each milling function, reducing manual intervention, and lowering the risk of errors, resulting in faster, more consistent production.Q: What materials can be processed with this desktop milling machine?

A: This milling machine is suitable for cutting and shaping a wide range of industrial and commercial materials, including metals, plastics, and composites, depending on the selected tooling and settings.Q: Where is this milling machine manufactured and supplied from?

A: The desktop milling machine is manufactured, supplied, and serviced by a reputable company based in India, ensuring local support and accessible maintenance options.Q: When should the machine undergo maintenance for optimal performance?

A: Routine maintenance is recommended every few months, depending on usage intensity. Refer to the user manual or consult the supplier for specific intervals to ensure the machine remains in peak condition.Q: What are the key benefits of using this high-efficiency milling machine in an industrial setup?

A: By offering high performance and efficiency with automatic operation, this machine reduces downtime, increases production rates, and saves operational costs, making it ideal for demanding industrial environments.Q: How do I utilize the full table size for larger projects?

A: To utilize the 9.14 x 6.17 inch table size effectively, securely clamp your workpiece and adjust the program settings via the PLC control to accommodate the dimensions, enabling precise milling for larger components.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS